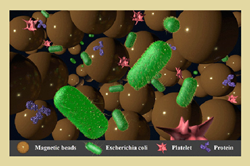

An enlarged image of the different bioparticles found in a specimen including the micro-beads to better isolate bacteria.

ROCHESTER, N.Y. (PRWEB)

April 17, 2020

Engineering researchers developed a next-generation miniature lab device that uses magnetic nano-beads to isolate minute bacterial particles that cause diseases. Using this new technology improves how clinicians isolate drug-resistant strains of bacterial infections and difficult-to-detect micro-particles such as those making up Ebola and coronaviruses.

Ke Du and Blanca Lapizco-Encinas, both faculty-researchers in Rochester Institute of Technology’s Kate Gleason College of Engineering, worked with an international team to collaborate on the design of the new system—a microfluidic device, essentially a lab-on-a-chip.

Drug-resistant bacterial infections are causing hundreds of thousands of deaths around the world every year, and this number is continuously increasing. Based on a report from the United Nations, the deaths caused by antibiotics resistance could reach to 10 million annually by 2050, Du explained.

“It is urgent for us to better detect, understand, and treat these diseases. To provide rapid and accurate detection, the sample purification and preparation is critical and essential, that is what we are trying to contribute. We are proposing to use this novel device for virus isolation and detection such as the coronavirus and Ebola,” said Du, an assistant professor of mechanical engineering whose background is in development of novel biosensors and gene editing technology.

The lab team is interested in the detection of bacterial infection, especially in bodily fluids. One of the major problems for detection is how to better isolate higher concentrations of pathogens.

The device is a sophisticated lab environment that can be used in field hospitals or clinics and should be much faster at collecting and analyzing specimens than the commercially available membrane filters. Its wide, shallow channels trap small bacteria molecules that are attracted to packed, magnetic microparticles.

This combination of the deeper channels on the nano-device, increased flow rate of fluids where bacteria are suspended, and the inclusion of magnetic beads along the device channels improves upon the process of capturing/isolating bacterial samples. Researchers were able to successfully isolate bacteria from various fluids with a microparticle-based matrix filter. The filter trapped particles in small voids in the device, providing a larger concentration of bacteria for analysis. An added advantage of a smaller device such as this allows for multiple samples to be tested at the same time.

“We can bring this portable device to a lake which has been contaminated by E. coli. We will be able to take a few milliliters of the water sample and run it through our device so the bacteria can be trapped and concentrated. We can either quickly detect these bacteria in the device or release them into certain chemicals to analyze them,” said Du, whose earlier work focused on devices that use the CRISPR gene-editing technology and the fundamental understanding of fluidic dynamics.

Teaming up with Lapizco-Encinas, a biomedical engineer with expertise in dielectrophoresis—a process that uses electrical current to separate biomolecules—their collaboration provided the increased capability toward better pathogen detection, specifically for bacteria and microalgae isolation and concentration.

“Our goal is not only isolating and detecting bacteria in water and human plasma, but also working with whole blood samples to understand and detect blood infection such as sepsis. We already have a concrete plan for that. The idea is to use a pair of the nano-sieve devices for sequential isolation,” said Lapizco-Encinas, an associate professor in RIT’s biomedical engineering department.”

Du and Lapizco-Encinas were part of a team that consisted of mechanical and biomedical engineers from Rutgers, University of Alabama, SUNY Binghamton, and Tsinghua-Berkeley Shenzhen Institute in China to address the global challenges of disease pandemics. The new data is published in the article “Rapid Escherichia coli trapping and retrieval for bodily fluids via a three-dimensional bead-stacked nano-device,” in the journal ACS Applied Materials and Interfaces.

The research team is RIT engineering doctoral and graduate students Xinye Chen, Abbi Miller and Qian He; University of Alabama assistant professor of electrical and computer engineering Yu Gan and undergraduate student Shengting Cao; Ruo-Qian Wang, assistant professor of civil and environmental engineering from Rutgers University; Xin Yong, assistant professor of mechanical engineering from SUNY Binghamton; Peiwu Qin from the Center of Precision Medicine and Healthcare, Tsinghua-Berkeley Shenzhen Institute, China; and Jie Zhang, Carollo Engineers Inc. in Seattle.

Share article on social media or email: