Radiant Vision Systems Introduces New VIP™ (Vision Inspection Pack) Software License that Enables Simultaneous Evaluation of Light, Color, and Defects in Backlit Symbols

With VIP, Radiant offers the first complete solution for backlit symbol inspection, which simultaneously performs photometric measurement of light and color and machine vision-based registration and defect detection for efficient lab testing and production-level quality control.

REDMOND, Wash. (PRWEB)

May 18, 2020

Radiant Vision Systems, a leading provider of test and measurement solutions for illuminated components and displays, announces a new software extension for its TrueTest™ Automated Visual Inspection Software for photometric measurement and analysis. The VIP™ (Vision Inspection Pack) software license extends the standard photometric measurement capabilities of Radiant’s TrueTest Software, adding machine vision-based registration functionality to enable defect detection and precise light and color measurement of illuminated icons, text, and shapes. Using VIP, manufacturers can realize a complete solution for backlit component inspection in a single software platform.

“Evaluating backlit symbols is a unique challenge because the visual quality of each symbol is determined equally by its photometric properties as it is by its dimensional integrity,” says Doug Kreysar, Chief Executive Officer at Radiant Vision Systems. “Machine vision equipment has long provided an effective method for registering the area of distinct objects and shapes within images. Separately, photometric measurement systems have been designed to evaluate the relatively undefined distribution areas produced by light sources, or the rectangular measurement areas of displays. Backlit symbol inspection, therefore, has required either human inspection, or a combination of software or equipment—usually a photometric system and a machine vision system—each component accomplishing only part of the quality control objective. In the latter case, a photometric system measures the brightness and color of a symbol, while separately a machine vision system evaluates shape quality (performing defect detection within the registered area of a symbol). To address the need for greater efficiency in backlit symbol measurement in industries like automotive, aerospace, and electronics, Radiant has developed a new software extension for our TrueTest Software platform that combines these capabilities within a single system. With VIP, Radiant offers the first complete solution for backlit symbol inspection, which simultaneously performs photometric measurement of light and color and machine vision-based registration and defect detection for efficient lab testing and production-level quality control.”

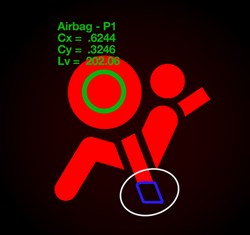

Leveraging machine vision software functionality, the VIP software license applies TrueTest photometric analyses for luminance (Lv), chromaticity (CIE xy, u’v’), and other values within the precise registration areas of unique shapes such as icons, text, and other backlit components. The VIP solution combines the standard measurement capabilities of TrueTest Software with defect detection to ensure trained measurement regions are free from inclusions or exclusions caused by inaccurate laser etch or errors in overlays, filters, or other substrate layers. In high-throughput inspection applications, VIP provides an efficient solution for rapid registration of multiple symbols and shapes captured within a single measurement image, and quickly applies trained registration regions to multiple components inspected in series. Registration regions can be applied globally (across multiple symbols) to ensure the accuracy of relative symbol locations, sizes, orientations, and aspect ratios; or locally (symbol by symbol) to dynamically register each symbol for measurement and defect detection. VIP automatically locates and registers symbols in new orientations (as components move or rotate) while maintaining the same relative placement of custom POI (points of interest) within each registration region. This ensures all symbols in a series of components are consistently measured based on the same POI locations, without requiring users to maintain exact fixturing tolerances or reapply registration regions or POI for each component measured.

Paired with a Radiant ProMetric® Imaging Colorimeter or Photometer, TrueTest Software with VIP provides a complete inspection solution for backlit components. The VIP solution enables manufacturers to:

-

Simultaneously inspect integrity of backlit icons, text, and shapes while measuring photometric values - Accurately apply registration regions and POI locations for each symbol if components move or rotate

- Simplify component placement and system fixturing

- Inspect multiple icons and shapes in a single measurement image

- Achieve highly efficient automated testing for quality control of multiple parts in production

For more information about the new VIP (Vision Inspection Pack) software license for TrueTest Software, visit http://www.RadiantVisionSystems.com.

About Radiant Vision Systems

Radiant Vision Systems works with world-class brands and manufacturers to deliver creative visual inspection solutions that improve quality, reduce costs, and increase customer satisfaction. Radiant’s legacy of technology innovation in photometric imaging and worldwide install base date back more than 25 years and address applications from consumer electronics to automotive manufacturing. Radiant Vision Systems product lines include TrueTest™ automated visual inspection software for quality control, and ProMetric® imaging colorimeters, photometers, and light source measurement systems. Radiant is headquartered in Redmond, Washington, USA, with strategic offices in California, Michigan, China, and South Korea. Radiant has been a part of Konica Minolta’s Sensing Business Unit since August 2015. For more information, visit http://www.RadiantVisionSystems.com.

Share article on social media or email: