The unique overhead design of our new t-Rail system helps both warehouse and in-store fulfillment operations deal with increased demand while also reducing labor requirements, minimizing floor congestion and human interaction and providing additional value for customers.

RALEIGH, N.C. (PRWEB)

August 13, 2020

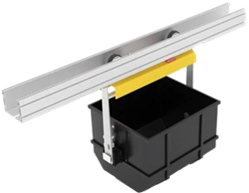

Tompkins Robotics, a business unit of Tompkins International, has expanded its product offering with the addition of t-Rail, an overhead robotic system capable of transporting a variety of goods and materials with speed and accuracy without disruption to floor-level activities. t-Rail can be deployed in distribution centers (DCs) and fulfillment centers (FCs) and is also used with Tompkins Robotics’ new micro-fulfillment solution to optimize operations in a retail store or backroom setting.

“The recent COVID-19 pandemic has accelerated an already burgeoning e-commerce market, causing many warehouses to exceed available capacity and forcing retailers to explore alternative options such as store-based fulfillment,” said Mike Futch, president of Tompkins Robotics. “The unique overhead design of our new t-Rail system helps both warehouse and in-store fulfillment operations deal with increased demand while also reducing labor requirements, minimizing floor congestion and human interaction and providing additional value for customers.”

Warehouses already operating at or near full capacity have limited space to implement new technology. t-Rail’s unique elevated design can carry bulk quantities of items or packages via a hopper or tote. The system utilizes elevators to interact with floor-level operations, allowing warehouses to maximize valuable space and eliminate traffic on the floor.

As warehouse space becomes more scarce and consumers continue to opt for buy online pick up in store (BOPIS) and curbside pickup options, many grocers and retailers are now utilizing brick-and-mortar locations for fulfillment operations. When used in a retail setting, t-Rail provides overhead transport of loose items, customer orders or cases of goods between the backroom and sales floor without causing aisle congestion or interference with in-store shoppers or workers, including:

-

Transporting totes of picked items from store aisles to the backroom for online order fulfillment - Delivering completed customer orders to their desired destination, including BOPIS lockers, drive-up windows or other pickup areas

- Delivering items from the backroom to specific aisle segments for store replenishment

In addition to the new t-Rail system, Tompkins Robotics is now offering virtual tours of its autonomous mobile robot (AMR) solutions in use at the company’s Orlando, Florida facility. The interactive tours demonstrate the various configurations and capabilities of Tompkins Robotics’ award-winning t-Sort systems, including the t-Sort, t-Sort Mini and t-Sort Plus models.

To learn more about Tompkins Robotics’ new t-Rail system or schedule a virtual tour, please visit http://www.tompkinsrobotics.com.

About Tompkins Robotics

Tompkins Robotics, a business unit of Tompkins International, is focused on the robotic automation of distribution operations. Our primary system, t-Sort, consists of autonomous mobile robots that sort a wide range of items and parcels to consolidation points. t-Sort is a portable, automated material handling sortation system that is creating a huge paradigm shift in the supply chain and how the basic distribution function of order fulfillment is accomplished. We continue to expand this core system with complementary robotic systems to automate processes in fulfillment operations. Our systems maximize performance with mobile, scalable and flexible robotics solutions that grow and change on demand to meet customer needs. We create profit and value for our clients, making them more agile and adaptable to the highly dynamic changes in the marketplace. For more information, please visit http://www.tompkinsrobotics.com.

About Tompkins International

Tompkins International is a global supply chain consulting and solutions firm dedicated to helping clients achieve supply chain excellence and profitable growth. Founded in 1975, Tompkins has integrated its decades of experience in strategy, commerce, logistics and technology into an ecosystem of four business units: Supply Chain Consulting, Material Handling Integration, Robotics and Applied Technologies. By combining best-in-breed services and technologies, Tompkins delivers a true end-to-end supply chain solution, enabling clients to improve the customer experience and ensure long-term success. Tompkins is headquartered in Raleigh, North Carolina and has offices throughout North America and in Europe and Asia. For more information, please visit http://www.tompkinsinc.com.

Share article on social media or email: