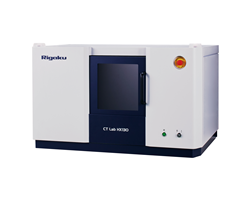

Rigaku CT Lab HX high-performance benchtop X-ray micro-CT scanner

The current newsletter features a preview of a number of upcoming events and webinars, many of which are employing the new Virtual Event model.

THE WOODLANDS, Texas (PRWEB)

September 30, 2020

The September 2020 edition of The Bridge newsletter from Rigaku Corporation is now available online on the company’s global website. The Bridge focuses on materials analysis, including informative articles and scientific papers, and features the latest news, techniques and instrumentation related to X-ray based materials science.

The current newsletter features a preview of a number of upcoming events and webinars, many of which are employing the new Virtual Event model. Details about upcoming web-based events, including the next in the series “X-ray Computed Tomography for Materials & Life Sciences,” are provided. The newest episode will explore ways to deal with unique challenges in life science sample preparation and introduce a variety of quantitative analyses.

Information about other upcoming events, including a virtual, interactive roundtable discussion with pharmaceutical industry professionals on how handheld Raman technology has transformed workflows and maximized quality insight in their organizations, as well as a webinar covering best operating practices—including appropriate sample preparation methods—for XRF users for industrial quality control is also featured.

A featured technical article for September details the examination of the internal structure of string cheese by X-ray microscopy and other techniques. The article studies the physical properties that confer string cheese with its texture and taste.

Another article describes the analysis of minerals in water by X-ray fluorescence spectrometry. The method employs the Rigaku Ultra Carry aqueous liquid sample carrier for trace element analysis, a novel application tool that enables parts-per-billion (ppb) level trace analysis.

A featured application report from Applied Rigaku Technologies, Inc. (ART) describes the analysis of gold alloys by energy dispersive X-ray fluorescence (EDXRF). The analytical technique is suitable for measuring the alloy chemistry of doré bars, ingots and foils, as well as other gold alloy materials.

The current issue highlights X-ray imaging systems, including the Rigaku nano3DX X-ray microscope (XRM). The nano3DX system has the ability to deliver 3D computed tomography (CT) images of relatively large samples at ultrahigh resolution. Also featured is the Rigaku CT Lab HX high-performance benchtop X-ray micro-CT system. It has the most powerful X-ray source in its class (130 kV, 39 W) and the advantage of a small footprint with low running costs. The powerful X-ray source covers a wide variety of applications, from polymer and bones to electronics and metals, and enables fast data collection at 18 seconds per scan.

A collection of news reports related to materials science, a featured video, and useful links are also included.

Readers can subscribe to the newsletter or view the current issue online at https://www.rigaku.com/subscribe.

About Rigaku

Since its inception in Japan in 1951, Rigaku has been at the forefront of analytical and industrial instrumentation technology. Rigaku and its subsidiaries form a global group focused on general-purpose analytical instrumentation and the life sciences. With hundreds of major innovations to their credit, Rigaku companies are world leaders in X-ray spectrometry, diffraction, and optics, as well as small molecule and protein crystallography and semiconductor metrology. Today, Rigaku employs over 1,400 people in the manufacturing and support of its analytical equipment, which is used in more than 90 countries around the world supporting research, development, and quality assurance activities. Throughout the world, Rigaku continuously promotes partnerships, dialog, and innovation within the global scientific and industrial communities.

For further information, contact:

Michael Nelson

Global Marketing Coordinator

Rigaku Corporation

michael.nelson@rigaku.com

Share article on social media or email: