Electrospinning nanofiber development services offered by Nanoscience Analytical.

We have experience helping our clients in a wide number of applications for electrospinning … Our team collaborates and provides the best possible finished formula to our clients to transfer from an R&D phase to a commercial production phase.

PHOENIX (PRWEB)

September 17, 2020

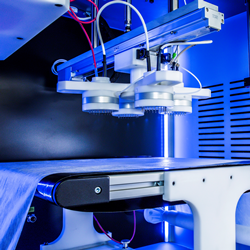

Nanoscience Analytical has recently increased laboratory space and expanded capacity for material development and electron microscopy services adding pilot-scale electrospinning equipment. The additional electrospinning systems now has expanded capability for roll-to-roll spinning, larger production, as well as larger production of electrosprayed microbead capacity. The additional equipment allows up to 112 simultaneous needles to electrospin nanofibers with integrated temperature and humidity control.

“The expansion of our instrumentation will allows us to bring clients further along in formulation and process development so they can create production level volumes of materials. We provide complete R&D and scale-up services, providing formulation recipes, and process engineering settings to easily transition our customers to full scale production in-house,” says Mark Flowers, Nanoscience Analytical president. “We have expertise in a variety of techniques with a broad range of materials and applications. Using state-of-the-art instruments, we provide our clients with specialized services and access to multiple, complementary analytical techniques and solutions.”

“Our electrospinning nanofiber development services has helped numerous companies expedite their research and development of new and novel materials for a wide number of applications,” says Dr. Francisco J. Chapparro, Electrospinning Scientist. “We have experience helping our clients in a wide number of applications for electrospinning. Applications range from nanofibers for improved air filtration to patches for wound healing patches and encapsulation of pharmaceuticals and therapies. Our team collaborates and provides the best possible finished formula to our clients to transfer from an R&D phase to a commercial production phase.”

In addition to increased electrospinning and electrospraying capacity, Nanoscience Analytical has increased SEM instrumentation and now has a Field Emission Scanning Electron Microscope (FE-SEM) that can obtain resolution under 3nm. This rounds out the other Microscopy capabilities which provide automated particle analysis and reporting, including elemental identification, sizing statistics, and spherosity. These techniques provide invaluable data for additive manufacturing, automotive parts cleanliness, foreign particle analysis, and many other QA/QC and R&D applications. Additional SEM sample preparation equipment include an ion mill and novel particle dispersant tool.

For more information about Nanoscience Analytical and the services provided, visit us online at http://www.nanoscience-analytical.com.

About Nanoscience Analytical:

Nanoscience Analytical, an ISO 9001:2015 certified facility, provides expert guidance and contract support for industrial research, production and quality assurance. Utilizing a targeted approach, we provide analytical services with state-of-the-art instrumentation and process development capabilities. Nanoscience Analytical specializes in a broad range of analytical techniques for surface science and nanoscale microscopy. Highlighted analytical services include aerosolized nanoparticle generation, nanofiber development, microscopy sample preparation, scanning electron microscopy and elemental identification, contact angle measurements and nanoscale mass detection services to quantify film thickness in liquid environments.

Share article on social media or email: