Kyocera at MD&M West

ANAHEIM, Calif. (PRWEB)

August 10, 2021

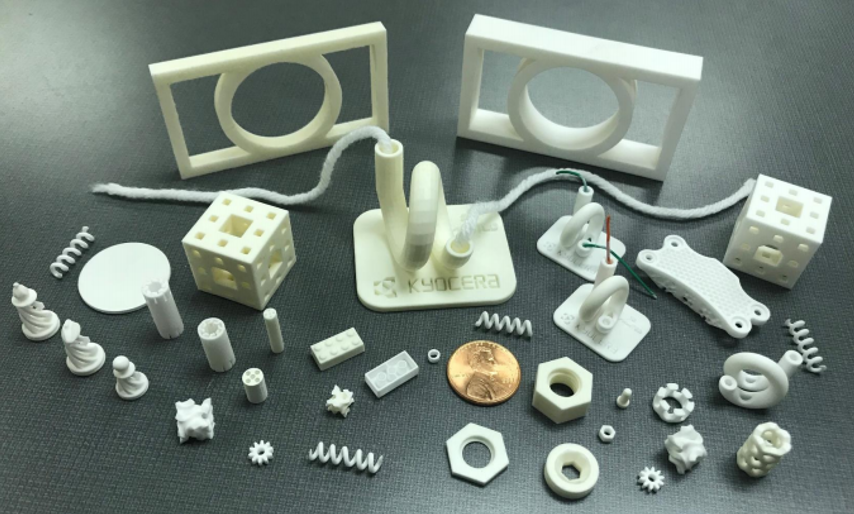

Kyocera, a leader in ceramics-based medical devices, will unveil its “CAM” (ceramic additive manufacturing) customized 3D printing service for cost-effective prototypes of new medical device designs at the MD&M West Medical Expo in Anaheim, Calif., August 10-12, the world’s largest annual convention for medical product designers and manufacturers. Kyocera’s new service utilizes both zirconia and alumina materials in a wide variety of shapes, a size range of 200 x 105 x 40mm and wall thickness of 0.25-10mm. The simple 3-step process rapid-produces samples: simply send a 3D CAD file, complete a consultation the next day and then prototypes are created in 1-2 weeks*. Additionally, Kyocera will also be showcasing its wide range of ceramics-based medical technologies during the expo.

Rapid Custom Samples with CAM

Incorporating 60+ years of product development expertise, Kyocera’s engineers consult on each new project and devise the most cost-effective method for a 3D printed prototype of new medical device designs. With that consultation and 3D printing using zirconia and alumina, Kyocera is able to produce virtually any kind of customized prototype in 1-2 weeks. Kyocera’s ceramics offer scratch resistance, higher rigidity, temperature resistance, longer lifetime, high-voltage insulation, lighter weight, and superior thermal management, providing an overall lower cost of ownership. 3D capabilities include:

-

Shapes: Curved, Square, Angled, Sharp edges, Angled holes, Negative draft, Threads, Textures, Tiny holes - Materials: Zirconia, Alumina

- Size: 200 x 105 x 40 mm

- Tolerance: +/-0.050 mm (as-fired)

- Wall Thickness: 0.25 – 10 mm

- Interlocking Assembly

- Smooth Surface

Additive Manufacturing and More @ Kyocera Booth #2363 MD&M West

According to MD&M West, the global medical device manufacturing market is expected to exceed $200 billion by 2025, largely due to an aging population, chronic disease and advancements in technology to help various conditions. Kyocera continues to use its unique ceramic “superhero” materials to help advance medical technologies. The Company’s Fine Ceramics provide a highly durable, long-lasting, non-reactive material that can be found in solutions for genetic sequencing; microfluidic tools; X-ray, PET, MRI and CT scan machines; pacemakers and cardiac monitors; neuromodulation devices; surgical tools; drug testing devices and orthopedic joint replacement systems. Information on these innovative ceramic medical solutions and more will be on display at Kyocera’s booth throughout the show.

Click to learn more about Kyocera’s medical solutions. To schedule a dedicated booth appointment or for more information on “CAM,” please email FCsales@kyocera.com.

*Rapid production in 7-14 days if hard grinding or polishing is not required. Each project production timeline will be estimated based on consultation.

About KYOCERA

Kyocera Corporation (TOKYO: 6971), the parent and global headquarters of the Kyocera Group, was founded in 1959 as a producer of fine ceramics (also known as “advanced ceramics”). By combining these engineered materials with metals and integrating them with other technologies, Kyocera has become a leading supplier of industrial and automotive components, semiconductor packages, electronic devices, smart energy systems, printers, copiers, and mobile phones. During the year ended March 31, 2021, the company’s consolidated sales revenue totaled 1.5 trillion yen (approx. US$13.8 billion). Kyocera is ranked #603 on Forbes magazine’s 2021 “Global 2000” list of the world’s largest publicly traded companies, and appears on The Wall Street Journal’s latest list of “The World’s 100 Most Sustainably Managed Companies.”

Share article on social media or email: