Asymmetrex reports algorithms for rapid quantification of therapeutic stem cells

“Determining the dose of therapeutic stem cells is now more than just possible for the first time. With ARMI’s support it’s getting easy to do, too!”

BOSTON (PRWEB)

June 09, 2022

In 2021, stem cell biotechnology company Asymmetrex announced its award of a Technical Project grant from ARMI|BioFabUSA. ARMI assembles, integrates, and leads academic, government, and industry partners in coordinated research and development with a unique vision of accelerating innovation in the biomanufacturing of products and treatments for regenerative medicine. Asymmetric became a member company of ARMI|BioFabUSA less than a year before being selected to evaluate whether its unique tissue stem cell counting technology could be successfully adapted for use in cell and tissue biomanufacturing.

Now, a little over a year later, the company is reporting the results of its evaluation in two presentations in ARMI|BioFabUSA’s Spring Meeting in the Millyard R&D summit, scheduled for September 7-9. On the opening morning of the summit on September 7, Asymmetrex presented an interactive Technology Demonstration of the capabilities of the newly automated software for its kinetic stem cell (KSC) counting technology. Automation is one of the four main ARMI|BioFabUSA principles for accelerating biomanufacturing capability. The others are modularity, scalability, and closed operability.

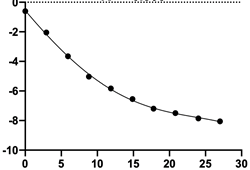

The new software automation provides a tenfold increase in the speed of determinations of changes in the relative fractions for tissue stem cells and their related cell subpopulations during biomanufacturing. No other technology has this capability; and the new software automation allows it to be performed with greater speed and even greater precision.

Asymmetrex’s second presentation was a poster displayed at the summit’s poster session on the evening of September 8. The poster provides a first look at the industry potential of validated rapid-counting algorithms for therapeutic stem cells. The speed and precision achieved by the software automation makes the derivation of these unique biological equations routine. Called “Rabbit algorithms” for their speed, Asymmetrex is currently developing online calculators for access to their use. The calculators use simple conventional cell count data to determine the specific fraction or dose of the tissue stem cells present in a biomanufacturing or treatment sample.

The facility and speed of the rapid stem cell counting algorithms enable straightforward integration of KSC counting for monitoring therapeutic stem cells in cell and tissue biomanufacturing processes. Asymmetrex is now designing a pilot online rapid-counting beta-test with ARMI|BioFabUSA bioengineers who collaborated in the research. Asymmetrex founder, James L. Sherley, M.D., Ph.D., expresses the company’s excitement with the new advances, “Determining the dose of therapeutic stem cells is now more than just possible for the first time. With ARMI’s support it’s getting easy to do, too!”

Asymmetrex, LLC is a Massachusetts life sciences company with a focus on developing technologies to advance stem cell medicine. The company’s U.S. and U.K. patent portfolio contains biotechnologies that solve the two main technical problems – stem cell-specific quantification and stem cell expansion – that have stood in the way of more-effective use of human adult tissue stem cells for regenerative medicine and drug development. Asymmetrex markets kinetic stem cell (KSC) counting, the first technology for determination of the dose and quality of tissue stem cell preparations for use in stem cell transplantation medicine and pre-clinical drug evaluations. Asymmetrex is a member company of the Advanced Regenerative Manufacturing Institute | BioFabUSA (ARMI) and the Massachusetts Biotechnology Council (MassBio).

Share article on social media or email: