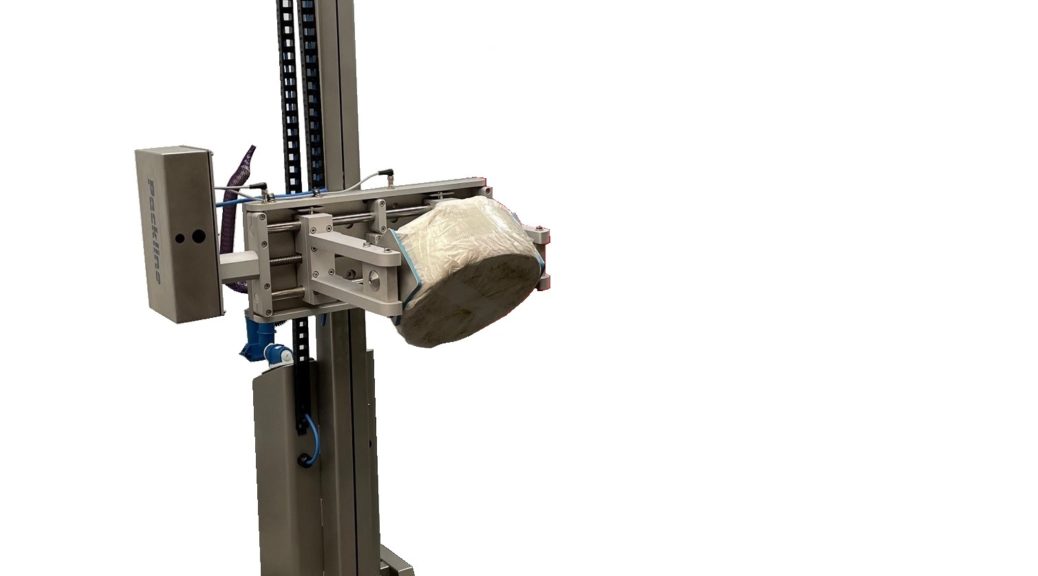

Stainless lifting equipment with clamp attachment for lifting and rotating rolls of cheese

The stainless clamp attachment with powered clamping and manual rotation for handling rolls of cheese is the ideal solution to increase efficiency and improve health and safety conditions.

KANSAS CITY, Miss. (PRWEB)

December 09, 2021

New to Packline Materials Handling and Ultrasource LLC, the stainless clamp attachment with powered clamping and manual rotation was designed in response to a customer enquiry in the cheese processing industry to lift, transport and rotate rolls of cheese in confined spaces. Constructed from stainless steel, this roll handling solution is suitable for clean room high care environments such as the food processing industries.

The rotating clamp attachment is smaller and narrower than the standard clamp with a new bespoke rotation system for the very small clamp attachment, with locking indents to hold fixed positions at pre-set angles.

The cheese is stored on racks to mature and turned 180 degrees every few days. The clamp attachment has been redesigned with a low profile and very narrow rotation head to enable the clamp to access the cheese on the racks and rotate them by 180 degrees.

The cheese is regularly transported to a washing area to be washed at a 45-degree angle on both sides of the cheese. The lifter transports the cheeses to the wash area and securely holds the cheese at the required angle.

The clamp attachment maintains the required fixed angle of 45 degrees by means of bespoke threaded ball index plungers and locking indents, suitable for the narrow rotation mechanism.

The clamp attachment features electric clamping incorporating a low-capacity torque limiter ensuring the clamp does not overtighten and damage the cheese.

The lifting equipment incorporates powered lifting and clamping, with manual rotation.

This lifter is entirely suitable for the food industry and other hygienic applications and features FDA approved nitrile rubber rollers. The design offers impressive stability, strength, and durability and together these features combine to provide the transportation of the rolls with ease, confidence and compete safety.

The attachment is backed up by a full bespoke design service ensuring the right solution can be made to suit most applications and requirements.

All Packline attachments are fully interchangeable and can be easily fixed or removed from any model of ‘Compac’ lifting machine that is fitted with the quick release system.

This attachment has a lifting capacity of 88lbs / 40kg depending upon the machine model.

The attachment has been designed to provide strength, durability as well as improved wear resistance and enhanced ease of use which provides a simple and safe action.

This stainless-steel roll lifting machine is suitable for use in the following industries:

- Food

- Drinks and Beverages

- Dairy

- Pharmaceutical

- Medical

- Chemical

- FMCG (Fast Moving Consumer Goods)

- Printing and Labeling

The purpose-designed compact framework, positioning of handlebars and addition of an optional remote-control device provide improved maneuvrability and ease of use for the operator.

The small footprint makes this drum handling equipment highly maneuvrable and a natural choice for today’s narrow production lines and demanding lifting requirements.

For further information on this roll lifter, or the full range of lifting and handling equipment, please contact Packline Materials Handling, or contact Ultrasource LLC in the USA for more information on the ‘EZ Lift’.

Packline Ltd

Unit 28

Newtown Business Park

Ringwood Road

Poole, Dorset

BH12 3LL, UK

https://www.packline.co.uk/

USA Distributor:

Ultrasource USA LLC

1414 West 29th Street

Kansas City, MO 64108-3604

(O): 816.360.2034 | Ext 2034

https://www.ultrasourceusa.com/ez-lift-film-roll-material-handling-equipment.html

For a full list of worldwide distributors please visit Packline’s website.

Share article on social media or email: