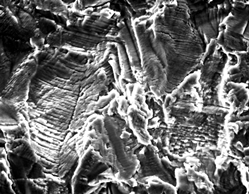

Fatique Striations Failure Analysis

Failure Analysis and Metallography will discuss:- Ductile and brittle fracture surfaces and how to recognize them- Fatigue fracture types- Failure due to corrosion- Failures caused by microstructural changes- Failures due to embrittlement

SHANGHAI (PRWEB)

September 15, 2021

The 9-11 attack of the World Trade Center buildings 1, 2 and 7, and the 1979 failure of the Three Mile Island Unit 2 nuclear reactor are classic examples of failures that required an analysis on what happened to the materials during very serious failures. Examples will be discussed in this webinar. Registration is available HERE.

Metallographers are brought in to analyze and identify what caused the problems and how they can be dealt with to stop the problem and any potential further damage and also to determine what can be done to prevent future problems.

Buehler is sponsoring a webinar “Metallography and Failure Analysis” on September, 28, 2021, 9:30am CST (China Standard Time). George Vander Voort, exclusive consultant to Buehler, will present this educational webinar. Failure analysis consists of studies to determine why a component failed in service.

With more than 50 years of experience in metallography and failure analysis, George will discuss fundamental principles of performing a failure analysis, as well as utilizing metallographic techniques to investigate failures and determine why they occurred and how they can be prevented.

Practical examples of the use of light optical and electron microscopy will be demonstrated through examples of failed specimens with a variety of case histories and studies, including:

- Ductile and brittle fracture surfaces and how to recognize them

- Fatigue fracture types

- Failure due to corrosion

- Failures caused by microstructural changes

- Failures due to embrittlement

- Highlight common problems

- Discuss key techniques to ensure success

A live question and answer session will follow the presentation. The webinar is ideal for metallurgists, metallographers and specimen preparation technicians, new engineers, quality control and laboratory personnel in any metallography facility new to the area or looking for a refresher on preparation and analysis of failed components.

Registration is complimentary and a replay will also be available. Attendees will receive a Certificate of Participation after the Webinar. To register for the complimentary webinar visit http://www.buehler.com. If the Webinar interests you, but the date does not suit you, simply register to receive the recording shortly after the event. Additional upcoming topics are also listed at the bottom of the Buehler webinar registration page.

Since 1936, the company has been a leading innovator in metallographic and hardness testing equipment and consumables for material specimen preparation. Contact a Buehler expert today! For additional information on Buehler’s products for material analysis or hardness testing, please visit http://www.buehler.com.

Buehler, an ITW Company maintains an extensive global network of laboratory, sales, distributors and service teams that are available to meet virtually or in person with customers worldwide. The Asian business office and plant is in Shanghai, China +86 400 111 8683 Email: Info.cn@buehler.com. Buehler also has an office in Japan +81 3 5439 5077 Email: info.japan@buehler.com. For additional information, email: marketing@buehler.com.

Share article on social media or email: